On this page, the Pound Wood Warden, David Harris, describes how we convert the local wood into charcoal.

Editor’s note: This web page is currently being revised to incorporate larger images. The formatting is provisional whilst it is tried out on various browsers and screen resolutions.

To allow for a good-sized image, the caption for each image is hidden, but is revealed (superimposed over the image) if you hover the mouse over the word Caption below the image (no need to click). When you move the mouse away, the caption will disappear.

If you print the page (or look at the Print Preview), the sections are displayed one after the other, with the caption printed below each image. You may need to refresh the page if the Preview does not show all the images.

Why should you buy local charcoal?

Much of the barbecue charcoal on sale in Britain is imported from the far east. Such charcoal is often produced from non-sustainable resources. That is, it is produced by using wood from trees which have been grubbed out or have been cut down and will not re-grow. It also uses our precious energy resources to transport it long distances. The charcoal you see here has been produced from British native hardwood trees which have been coppiced as part of countryside management for the benefit of wildlife. The trees which have been cut to produce it will grow again from their roots to produce another crop of wood for harvesting in about 20 years time. There is a never-ending supply of this wood and so the source is sustainable indefinitely (unlike tropical rain forests). The charcoal has been made in Thundersley, Essex which is local to our customers and so there is very little energy used in transporting the product.

Next

Converting local wood into charcoal (02)

First

Previous

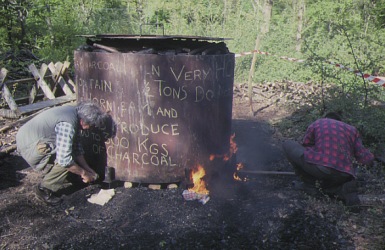

CaptionThe charcoal is burned in a large metal kiln approximately two metres

across and one and a half metres high (see above).

It is important to start with an empty kiln, to ensure that the air vents are not blocked.

Next

Last

Converting local wood into charcoal (03)

First Previous CaptionThe kiln must be positioned carefully so that it is horizontal, and the air vents are not blocked on the outside. It should also be clear of any surrounding vegetation. Next Last

Converting local wood into charcoal (04)

First Previous CaptionThe burn area is cordoned off to deter casual visitors from getting to close for safety. Next Last

Converting local wood into charcoal (05)

First Previous CaptionThe logs are cut to about 50cm and stacked inside the charcoal kiln ensuring that there is adequate ventilation at the bottom, including a radial channel from each air vent. Then other cordwood is stacked on top of this, gradually building up layers, whilst leaving a central free space. This can be filled with the partly-burnt remains from the last burn. Next Last

Converting local wood into charcoal (06)

First Previous CaptionThis kiln, when full, holds about one and a half tonnes of cordwood. Next Last

Converting local wood into charcoal (07)

First Previous CaptionFor this kiln, the load needs to be about 20cm above the rim of the kiln before firing. Next Last

Converting local wood into charcoal (08)

First Previous CaptionA fire is then started at the bottom in the centre of the kiln using lighted, paraffin-soaked rags. Next Last

Converting local wood into charcoal (09)

First Previous CaptionLighted paraffin-soaked rags are pushed through the air ducts on which the kiln rests. Next Last

Converting local wood into charcoal (10)

First Previous CaptionAs the fire takes hold in the centre of the kiln, considerable amounts of white, steamy gases are produced. The volume of this will depend on the age of the wood. Well-seasoned wood will produce much less smoke than newly coppiced wood. Next Last

Converting local wood into charcoal (11)

First Previous CaptionWhen sufficient wood has been consumed to allow the lid to fit snugly onto the kiln, soil is piled around the base of the kiln to restrict the ventilation to just four air inlets. Next Last

Converting local wood into charcoal (12)

First Previous CaptionLong flues are attached to the other four air ducts so that they become chimneys. The fire is then able to burn only at the bottom of the kiln. The resulting heat is sufficient to drive off the moisture and other volatile contents of the wood above to leave just the carbon behind. This is charcoal! Next Last

Converting local wood into charcoal (13)

First

Previous

CaptionThe kiln itself has now become hot, and warning signs are necessary to deter

casual visitors.

The kiln is closed down by excluding all air and is allowed to cool for a day or two.

The kiln can now be left for as long as it necessary to complete the burn, and then to cool down. It is

important that the kiln is not opened too soon. Whilst there is still residual heat, there is the

possibility of spontaneous combustion from still-hot charcoal.

Next

Last

Converting local wood into charcoal (14)

First Previous CaptionAfter the burn, the kiln is opened to reveal the charcoal. The contents of the kiln have settled down to about three quarters of the volume and about a sixth of the weight. Next Last

Converting local wood into charcoal (15)

First Previous CaptionMuch of the original structure of the cordwood is still to be seen in the charcoal, especially near the top of the kiln. It is quite fragile and is removed by leaning into the kiln and picking each piece up by hand and transferring it carefully into a large temporary storage sack. Next Last

Converting local wood into charcoal (16)

First

Previous

CaptionThe charcoal near the bottom will have collapsed under

the weight of the contents above.

When arms are unable to reach any lower, the soil around the base of the kiln can be cleared, and the

kiln itself tipped over.

Next

Last

Converting local wood into charcoal (17)

First Previous CaptionThe kiln is then tipped over to release the contents. Next Last

Converting local wood into charcoal (18)

First Previous CaptionNow comes the job of packaging the charcoal into bags ready for sale! Next Last

Converting local wood into charcoal (19)

First Previous CaptionHandling and sorting charcoal can be a very dusty process. Our customers do not want dust in their charcoal and so it is filtered as required using a simple sieve. Next Last

Converting local wood into charcoal (20)

First Previous CaptionThe charcoal is then carefully transferred by hand from the large temporary storage into paper sacks which are then labelled appropriately. Next Last

Converting local wood into charcoal (21)

First Previous CaptionThe packaged charcloal is available for sale at the Trust’s Visitor Centres and at our open days. Here there is a display of woodland products at the 2008 Bluebell Day at Pound Wood, including bagged charcoal. Next Last

Other sites about Charcoal Burning

The Charcoal Burners is a site describing a local charcoal-burning group in Hampshire.